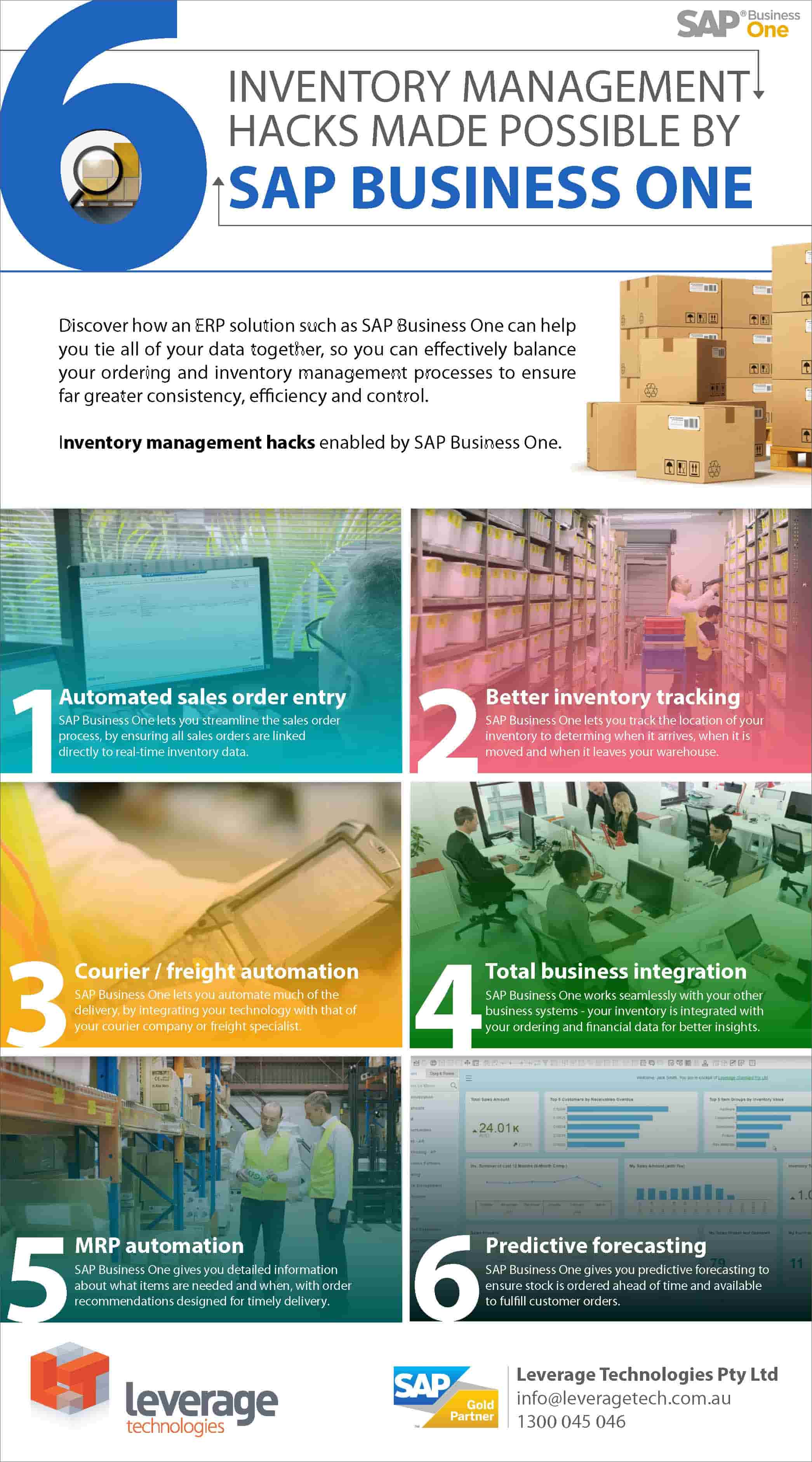

6 Inventory Management Hacks Made Possible By SAP Business One

In the manufacturing sector, inventory management can be both time consuming and difficult.

To operate effectively and productively, you need to know exactly where your inventory is at all times – including when it arrives at your warehouse, where it is located within your warehouse, and when it leaves. Plus, you need to prevent your inventory from becoming too high – to avoid storing items at unnecessary cost – or too low, which can lead to a costly out-of-stock situation.

The smart approach the inventory management

Fortunately, advances in technology have given manufacturers and distributors access to a range of tools that enable far more effective inventory monitoring and control at every step. While remote, internet-connected devices enable you to capture data on your inventory, an ERP solution such as SAP Business One can help you tie all of your data together, so you can effectively balance your ordering and inventory management processes to ensure far greater consistency, efficiency and control.

Here are six key inventory management hacks enabled by SAP Business One.

1. Automate the sales order entry process

Manually checking inventory levels to fulfil sales orders can be time-consuming, difficult and prone to error. Unless the process is backed by real-time data on your available inventory, you have no way of knowing exactly when a product will be available for the customer, or when it can be dispatched.

With SAP Business One, however, you can automate and streamline the sales order process, by ensuring all sales orders are linked directly to real-time inventory data.

For instance, when a sales order is received via SAP Business One, the system will automatically check for availability in your warehouse. If the items are confirmed as being available, then the quantity is committed in the inventory – preventing overlap from concurrent orders and ensuring your order and inventory levels match up. The information is then made available to your warehouse staff, who can remove the products from the warehouse ready for dispatch. Once an order is collected from the warehouse, it is also then entered into the system – and the reduction in inventory is automatically registered.

By automatically connecting demand from sales orders with the feasibility of stock levels, you can provide better customer service, make life easier for your staff, and avoid situations where there simply isn’t enough inventory to fulfil an order.

2. Scan goods when they arrive/depart the warehouse

The Internet of Things (IoT) has already revolutionised the manufacturing sector on a global scale, enabling manufacturers to access, gather and use real-time data on their inventory – regardless of where it is, or what step of the supply chain it’s at.

For instance, by putting internet-connected scanners in your warehouses, and feeding this information into a system such as SAP Business One, you can automatically track the location of your inventory – determining exactly when it arrives at your storage facility, when it is moved to another location within your facility (or even between warehouses), and when it leaves.

This means everyone in your business has ready access to information on the location of specific inventory from any device, regardless of whether they are in head office, or on the warehouse floor.

3. Integrate warehouse solution to your courier company/ freight specialist

With a solution such as SAP Business One, you can also automate much of the delivery, by integrating your technology with that of your courier company or freight specialist.

The team at Leverage Technologies has, for instance, developed a SmartFreight® integration solution specifically for SAP Business One. This freight management solution provides generic multi-carrier freight management and can be used as a single solution across multiple freight companies.

With SmartFreight®, you can automatically initiate your delivery requests, and can also track a package from the moment it leaves your warehouse to the time it arrives at an end customer.

4. Integrate warehouse, production and accounting

As SAP Business One works seamlessly with your other core business systems, all of your inventory data is integrated with your ordering and financial accounting data – meaning you receive overarching insight.

For instance, when a goods receipt for an ordered item is posted, your SAP Business One software will automatically update the inventory in the warehouse and inform the warehouse manager of the expected delivery date. It can also update the related vendor and expense accounts. As SAP Business One captures information at every step of a transaction, you always know what’s on hand in your inventory, and will always have the up-to-the-minute financial status of your business from your desktop or mobile device.

5. Use material requirements planning to ensure the right stock levels

Ensuring that your stock is at optimal levels can be very challenging, and you want to avoid costly out-of-stock situations at all costs.

SAP Business One supports purchasing planning and helps you set your reorder points correctly so you avoid unnecessary purchasing that would otherwise result in inventory carrying costs. Using the material requirements planning wizard in SAP Business One, for instance, you can forecast and plan your material and non-material needs and schedule your purchases accordingly.

SAP Business One gives you detailed information about what items are needed and when. Its order recommendations even take into account lead times, providing the optimal purchase date for a timely delivery of the products you order.

6. Use predictive forecasting to ensure stock is ordered ahead of time and available to fulfil customer orders

To be as responsive as possible to your customers, you need to accurately plan your inventory in keeping with predicted demand. With SAP Business One, you can use the sophisticated material requirements planning functionality to achieve this. Rather than planning your inventory levels based on ad-hoc information, you can use data from various sources to get an accurate picture of your production and supply chain. This data can include bills of materials, inventory data, input from scheduled production and purchase orders and demand derived from actual and forecasted orders.

SAP Business One also helps you plan the purchase of items based on sales forecasts, minimum and maximum quantity levels, and demands made through the warehouse.

Case study: How W9 saved money by improving its inventory control

W9 Australia is a well-known importer, distributor and wholesaler of medical and dental products. W9’s products are distributed nationally across Australia and are also exported internationally. In 2004, the business determined that its previous software was restricting its growth, and wasn’t offering the insight or level of detail they required. W9 decided to implement SAP Business One, and engaged Leverage Technologies to help them do so.

W9 wanted a software solution that could be expanded as the business grew in size, and which would provide tight financial control, strong inventory control and enable seamless distribution. Being a healthcare and medical distributor, it’s vital that W9 has strong serial and batch tracking on their products. SAP Business One allows us the business to achieve this level of control, in conjunction with their existing Resolve warehouse management system.

As a result of the new system, W9 has been able to streamline its picking, packing and fulfilment of orders, shorten the ‘order to cash cycle’, and evolve its procurement and supply chain logistics. W9 has enjoyed a range of benefits, and thanks to enhancements by Leverage Technologies, has reduced its overall order processing times by 50%.

Watch the full case study here >https://www.youtube.com/watch?v=90oQGSbbE6M

Want to learn more? Chat to Leverage Technologies

Leverage Technologies is a leading technology firm with extensive experience in the manufacturing sector. As a trusted SAP Partner, we have extensive experience in deploying SAP Business One for a range of businesses, and across several industries.

To find out more about SAP Business One, submit the contact form or give us a call on 1300 045 046.

A complete inventory management plan must provide for end-to-end control over all related assets – including how they are utilized. Be sure to create and document formal policies and rules related to technology usage. And, make it clear what action will be taken if policy violations are detected.

Many companies that manage an inventory grow such that their products are stored in more than one location, whether it’s another warehouse or even on a truck or trailer. The ability to see which items are located by warehouse is extremely helpful. Some systems allow you to manage inventory in multiple locations, and even let you make transfers within the software when necessary. The ability to view inventory by location keeps you more organized and allows you to get the inventory you need more quickly.