Batch Traceability in SAP Business One For Process Manufacturers: How does it Work?

Process manufacturers need to be able to follow raw materials and ingredients back to their origin to ensure the quality and safety of the products they sell. This post explains how SAP Business One improves batch and lot traceability.

Extreme care and accuracy is required when you’re making food and beverages for consumption, life-saving drugs and other pharmaceuticals, or dangerous chemicals.

Understandably, process manufacturing is governed by strict industry guidelines and regulations in order to produce safe and effective products. But manufacturers also need tight control over production and quality assurance processes to meet customer needs.

To remain compliant and achieve true transparency, one important feature process manufacturers need from their Enterprise Resource Planning (ERP) solution is batch traceability.

SAP Business One makes it straightforward to understand and track a product’s complete life cycle using batch and lot codes.

Growing health and safety concerns put the spotlight on food processing

The food processing industry is under particular scrutiny because what we eat and drink is such an important driver of health, wellbeing and public safety. Meeting your HACCP risk assessment obligations is just the starting point.

Growing public health concerns mean health bodies and regulators are advocating changes that will impact manufacturers, such as: the World Health Organisation calling for the elimination of industrially-produced trans fatty acids (IPTFA); and public consultation run last year by the Australian Government around proposed changes to how information about sugar is included on labels.

In recently released statistics on food recalls in 2018, Food Standards Australia and New Zealand (FSANZ) highlighted a number of issues related to allergen-related recalls as a result of poor labelling, supplier miscommunication, packaging errors and accidental cross-contamination. The most common way problems came to light was through complaints from customers, distributors and retailers.

It’s not possible to guarantee perfect production processes, but systems that support greater precision and traceability are essential to ensure you can effectively deal with recalls which can lead to life-threatening outbreaks and illnesses.

Your food processing business can achieve full traceability with batch and lot tracking functionality in SAP Business One.

Valuable batch traceability features in SAP Business One that your business needs

If you’re still planning production or recording batch information using spreadsheets it can be exhausting to monitor the movement of materials and goods throughout each stage of the supply chain. There’s also plenty of room for error and no easy way to audit data or ensure its integrity.

Implementing SAP Business One in your business enables you to gain granular control and visibility over production processes, as part of an integrated system for managing your whole business.

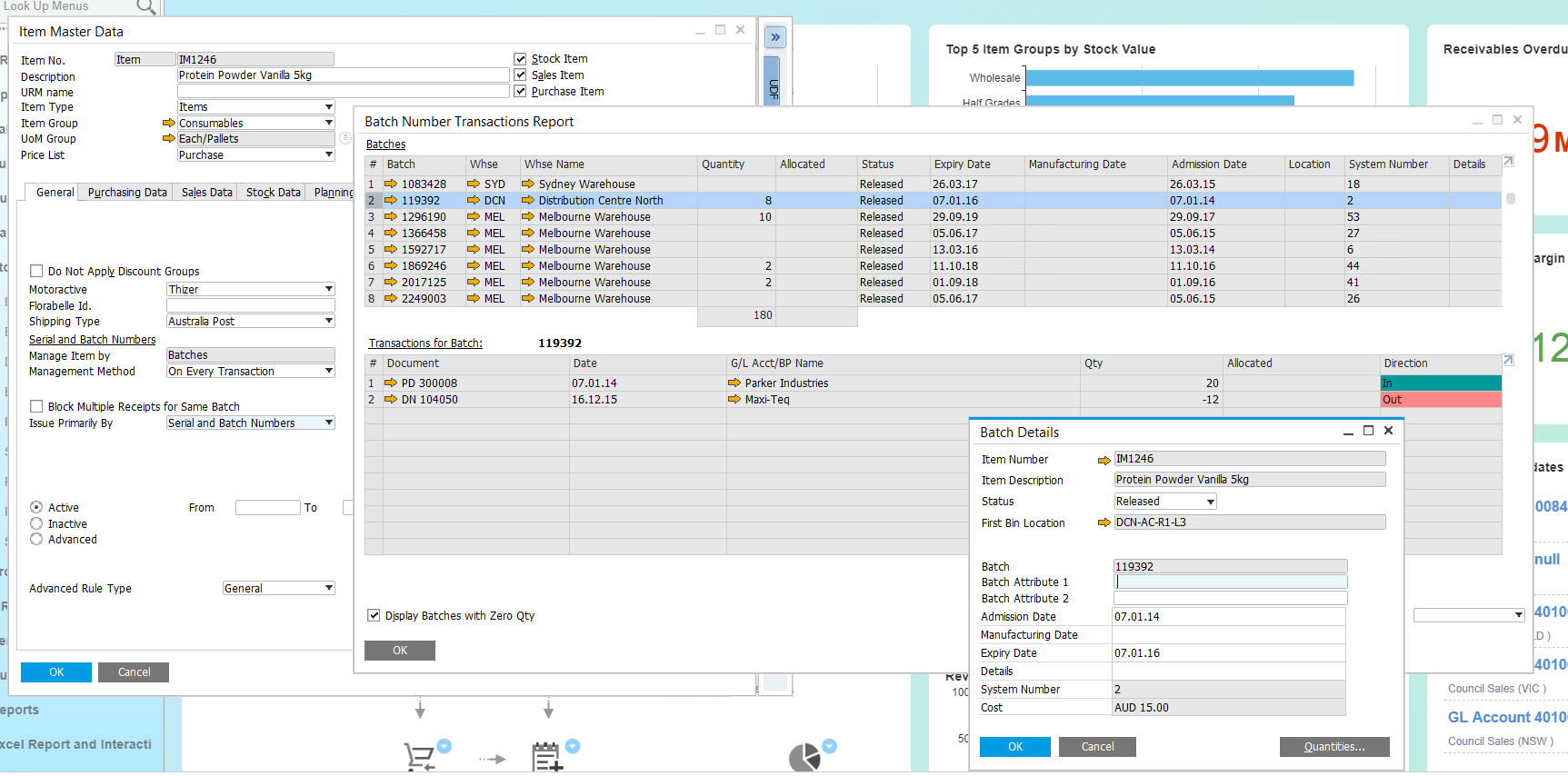

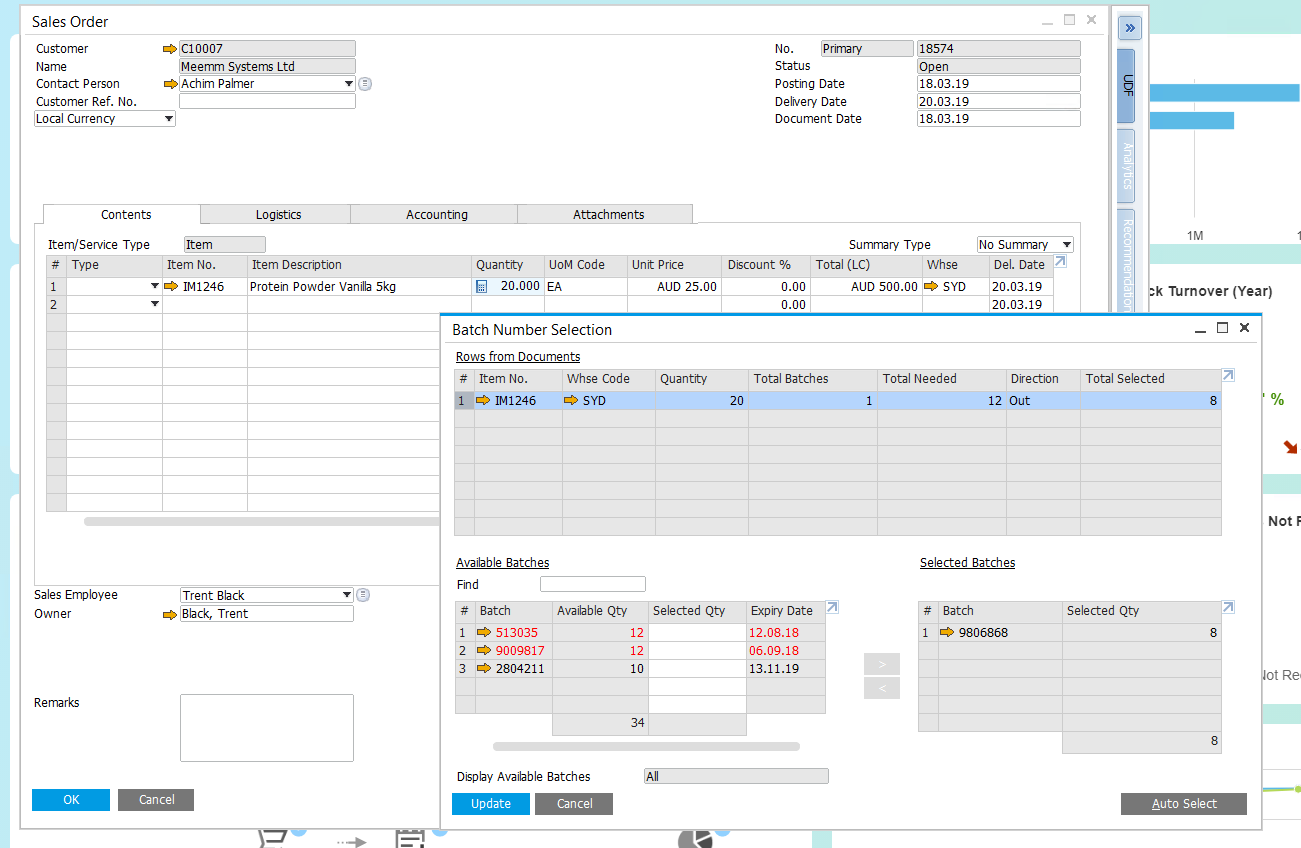

Designed with an in-depth knowledge of the challenges process manufacturers face, SAP Business One empowers you to use batch codes to track materials and products from procurement, during production, and through to sale.

The requirement to allocate a batch code can be enforced using rules set-up within SAP Business One to ensure procedures are followed to the letter.

You can batch track raw materials as well as the units created as part of a production order.

From a functional perspective, when a product is flagged as being batch tracked every movement is tracked and batch codes assigned for each transaction—so you know when it has been procured and receipted, which production order it’s associated with, which warehouse it’s stored in and whether it was moved between warehouses, when it’s sold and who to, and so on.

Batch traceability in SAP Business One ensures your business can:

- Track and determine the used-by date of products to manage shelf-life and perishable goods, improve turnover, and meet customer expectations.

- Quickly advise relevant customers when production issues are discovered, and manage recalls based on specific batches or production dates (goods produced on a certain date).

- Easily identify batches and specific customers affected by recalls initiated by suppliers of ingredients or raw materials.

- Track information like a batch’s certificate of analysis, for pharmaceutical and chemical products.

There’s almost an unlimited number of attributes you can tag against a batch, which provides an excellent source of data and accountability for manufacturers with complicated processes that complete large production runs.

Additionally, since you have details about each batch, you can complete product valuations by batch. That allows you to more realistically assess your costs and resource-use needs for production runs, identify issues, and adjust margins.

Let’s say you manufacture sandwiches. The system can help you determine the cost of a particular batch of sandwiches produced by analysing the number of sandwiches, the number of team members on the production line, the amount of ingredients used, etc. You can see the differences between batches, for instance depending on which bread supplier is used, or the workforce or time period.

That level of detail is important if you’re looking to not just remain compliant, but push your competitive advantage.

[FEATURE ARTICLE – 6 Tips for choosing the right ERP for your manufacturing business]

Track batches, maintain trust and function better with SAP Business One

Community needs and standards are changing and it seems likely that process manufacturers will face more rules in future as regulators seek to reassure consumers, avoid health and safety risks, and improve environmental outcomes.

Not meeting your compliance obligations and customer expectations can have serious impacts beyond the risk of fines or public safety—in the long-term you won’t be in a position to build trust, adapt to consumer needs and grow your market share.

Being able to demonstrate transparency across your supply chain is essential to help you stay ahead of the curve when it comes to responding to ever-evolving rules and consumer expectations.

Interested in learning more about SAP Business One’s batch traceability capabilities? Call 1300 045 046 or email info@leveragetech.com.au.

Leave A Comment